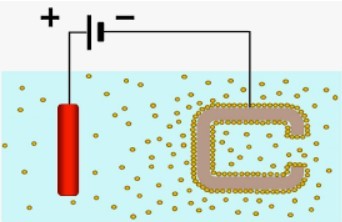

KTL (Kataphoretische Tauchlackierung) means cataphoretic v. cathodic dip painting.

During the KTL process, the workpiece to be coated has a negative charge, which is immersed in the positively charged paint bath, thus the paint particles are deposited on it. The particles in the paint bath form a uniform coating over the entire surface. Thus, each surface - including the edges - will be coated with the specified thickness. Using the KTL process, uniform layer thickness (15-40 μm) and good surface quality can be achieved both on the outer surface of the metal surfaces and in the inner parts.

The coating is electrically insulating,so an increase in layer thickness stops the paint shedding after a while. Taking advantage of this feature, the layer thickness requested by the customer can be easily adjusted by controlling the painting voltage. After painting, the coating is dried and hardened in the oven, thus acquiring its final properties.

If a large number of workpieces or complex structures need to be coated with a corrosion-and impact- resistant coating, KTL surface treatment is a solution worth considering. KTL is considered one of the most effective coating processes. The coating meets the strict requirements for automotive coatings, but it is also used with preference in other areas of the industry due to its durability, resistance and cost- effectiveness.

The components first undergo a thorough cleaning process. In alkaline baths, we remove all dirt from the surface, which is the basis of all surface treatments. After rinsing, the next important pretreatment step is tricationic zinc phosphating. The gray conversion layer created with a zinc phosphating solution has a microcrystalline structure, 1-2 micrometers thick, 1.5-2.5 g/m2 layer weight, results in good paint adhesion and increases resistance to corrosion. After rinsing with ion-exchanged water, the pretreated surface is placed in the tub containing the KTL paint.

One of the main advantages of KTL processes is the coating of external and hollow surfaces of components with very uniform coating thickness and good surface quality. The cathodic immersion bath surface treatment provides effective and long-lasting corrosion protection in addition to high temperature and chemical resistance. The cathodic coating is scratch-resistant and provides protection, e.g. against stone chipping. In addition, the KTL process is an environmentally friendly coating method, as the paint is water-based with a low solvent content. Our painting plant has its own wastewater treatment equipment, which ensures compliance with strict environmental regulations.

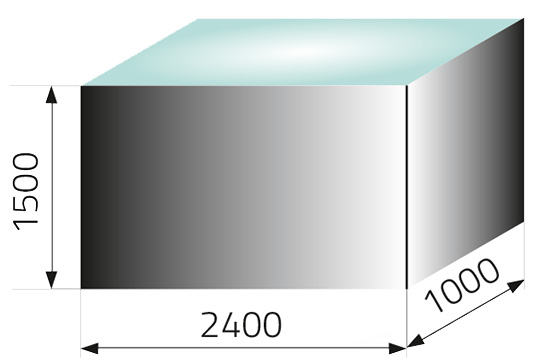

- Maximum size of workpiece: 2400x1000x1500 mm

- Total surface of work piece(s) that can be handled maximally: 20 sq. meter

- Total weight of work piece(s) that can be handled maximally: 600 kg

- Annual capacity: more than 1,5 million sq. meter 2400